Why choose Stereolithography (SLA)?

One of the biggest strengths of the parts produced using the Stereolithography process is their accuracy– SLA 3D Printed parts are able to be printed in high resolution which facilitates printing of fine details and superior surface finishes. The advantage of the stereolithography process is its ability to quickly produce parts with complex irregular features with a very high degree of precision.

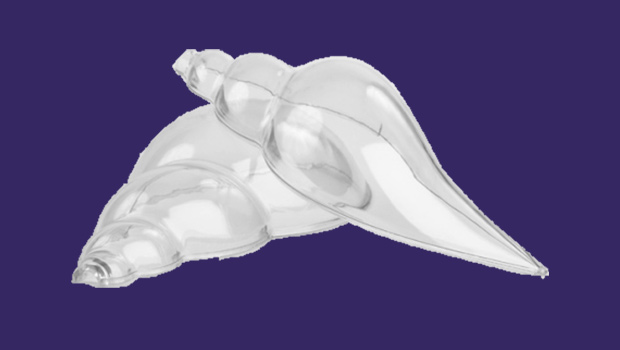

Models produced using the stereolithography process can be finished to a very high standard due to their smooth surface finish and this makes them particularly suitable as aesthetic “show and tell” models.

SLA 3D Printed parts are available in a wide range of engineered materials which offer excellent material properties and include a material which is USP Grade VI approved. This makes SLA parts ideal for functional testing.

Unsure if Stereolithography is the right technology for your project?

View our process comparison tableTechnical specifications

| Standard lead time: | 3- 5 days. If your project is urgent, please let a member of sales team know so that we can investigate if anything can be done to improve the lead time. |

|---|---|

| Minimum feature size: | Normal resolution: 0.15mm | High resolution: 0.08mm |

| Layer thickness: | Normal resolution: 0.1mm | High resolution: 0.05mm |

| Tolerances: | Typically, expected tolerances on well-designed parts are:Normal resolution: +/- 0.15 per 100mm | High Resolution: +/-0.10 per 100mm |

| Max part size: | Normal resolution : 650 x 750 x 550mm | High resolution : 450 x 450 x 415mm |

| Machines: | iPro 8000 | Viper Si2 | 3500 Machine | 250 Machine | 5000 Machine | NEO 450s |

Please note figures provided above are expected tolerances, we cannot guarantee part tolerance.

Materials

Xtreme

- Ultra tough, functional grey parts that resist breakage

- Physical properties simulate ABS and polypropylene

- Good moisture resistance and a thermal resistance of over 60°C

- Excellent accuracy and with the look and feel of a durable molded plastic

- Suitable for fit, form and function prototypes and durable assemblies

- Maximum part dimensions: 650 x 750 x 550mm

Watershed

- Water clear ABS like parts

- Produces highly detailed parts with superior clarity and water-resistance

- Optically clear parts with a smooth finish

- Certified USP Grade VI material

- Maximum part dimensions: 450 x 450 x 400mm

Taurus

- Charcoal ABS like parts

- Heat tolerance up to 90°C

- Excellent surface quality and isotropy for highly detailed parts

- Superior strength and durability

- Ideal for the most demanding functional prototyping and end-use applications

- Maximum part dimensions: 350 x 350 x 350mm

PerFORM

- Off-white ceramic filled parts

- Strong, stiff, high temperature resistant composite parts

- Excellent detail resolution

- Suitable for applications including high temperature testing, electrical casings and automotive housings

- Maximum part dimensions: 350 x 350 x 350mm

SL7820

- Black ABS like parts

- High strength and good dimensional stability (even in humid conditions)

- Replaces CNC-machined black ABS articles for functional assemblies and short run production parts

- Maximum part dimensions: 250 x 250 x 250mm

Si25

- White parts that simulate polypropylene

- Flexible plastic, suitable for snap fit assemblies

- Maximum part dimensions: 250 x 250 x 250mm

Finishing Options

LPE has a team of experienced in-house traditional model makers and a full spray-painting booth allowing us to offer our customers a range of finishing and painting options.

-

Standard

Components produced using the Stereolithography process are sanded to remove support structures and build lines and then bead blasted for an overall smooth finish.

-

Polished

SLA Watershed parts can be polished as clear as possible.

-

Metal Plating

It is possible to metal coat SLA parts in a range of different metals including chrome and nickel.

-

Medical grade clean-up

SLA parts can be given an ISO13485 medical grade clean up which means the parts can be used in a surgical environment.

-

Other paint finishes

It is possible to give SLA parts a range of paint finishes including cosmetic (Pantone/RAL colour matching), matt, satin, spark or gloss.

Applications

Stereolithography is suitable for low volume production and one-off prototypes.

Why LPE?

Our in-house additive manufacturing facilities consist of multiple state-of-the-art SLA machines and a wide range of materials offering superior mechanical properties.

LPE are an ISO 9001 & 13485 approved supplier, with over 30 years of industry experience. If requested we can provide first article inspection reports, certificates of compliance and will work with you to ensure any quality requirements in relation to your production requirements are met. We are a supplier of 3D printed components to both large and small organisations across the UK & Ireland. LPE has the capabilities to meet all your requirements for both prototyping and low volume production.

Customer service lies at the heart of everything we do at LPE, from tailored quotes to a personalised service. If you feel you could benefit from chatting directly to an expert about your project, contact us now.

Learn more about why you should choose LPE as your preferred SLA 3D printing partner.

Learn moreHow does SLA work?

The Stereolithography process is a 3d printing technique in which 3D CAD data is converted into physical solid models, layer by layer, by curing a liquid photopolymer resin with a UV laser. Structural supports are created during the setup process and these are then manually removed once the printing is completed. The parts are washed in a solvent solution to remove uncured resin and placed in a UV light oven to receive a final post cure. Support structures are removed with gentle sanding and bead blasting.

(028) 9070 6940

(028) 9070 6940  sales@laserproto.com

sales@laserproto.com